If you have recently started a renovation project, you have probably heard that the terms trim and molding are used interchangeably, and may be wondering what the difference is between the two.

Trim is a general term used to describe the material used around openings such as windows and doors, or at the corners between walls and ceilings, or at floor intersections. Molding can also be installed in the middle of walls, such as in the case of a chair rail or, more broadly, wainscoting.

Cornices are a type of decorative molding that distinguishes itself with its enhanced profile characteristics. Typically, they are molded to be more ornamental and detailed. An example of this is a ceiling cornice, which is used at the junction between walls and the ceiling to create visual interest or soften the transition between the wall and ceiling.

Contents

Types of Cornices

Cornices can be categorized into four main types, depending on whether they are installed around openings, on the ceiling, on the floor, or directly on the wall. Casing cornices are installed around openings such as windows and doors.

Skirting boards are positioned along the bottom of the walls, while cornice mouldings are installed near the ceiling. Finally, wall cladding refers to any cornice mouldings that are directly attached to walls and not to openings or corners.

Window and Door Casing

A casing is a type of trim used around openings. Doors and windows are the most common places. The casing acts as a frame around the openings and helps to cover gaps between the walls and window or door elements.

When it comes to door openings, the casing is installed at the top and alternately on the sides of the opening. At window openings, trim can be installed on all four sides of the window. However, typically, the lower part of the opening has a sill and apron, and the casing is installed at the top and on the sides.

Baseboard Trim

Baseboard trim, also known as wall baseboard, is installed at the bottom of walls. Baseboards not only add an accent to the wall, but they also help hide imperfections in the construction between the flooring and the walls of a room.

Usually, they are cut on mitered corners and trimmed on inside corners. If the floor is going to be carpeted, the baseboard is typically installed slightly above the subfloor. If hardwood floors are being used, the baseboard is installed after the wood flooring has been laid.

Crown Moulding

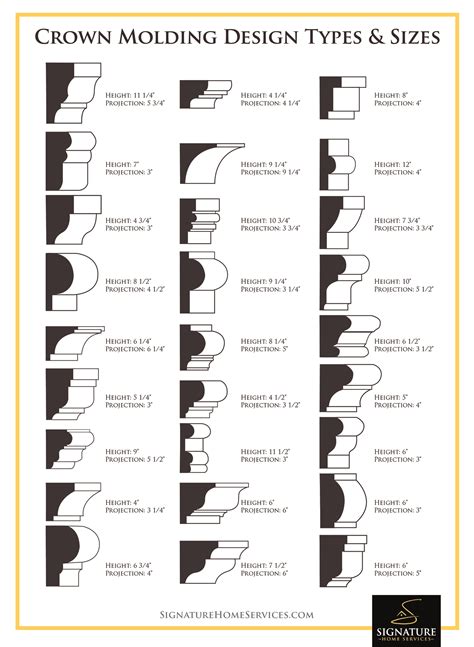

Crown moulding, also known as cornice moulding, is installed at the top of walls and contributes to the visual separation between the wall and ceiling. Often, decorative moulding can be intricately detailed to add a more elegant feel to the room.

Moulding comes in various profiles, from simple to highly ornate. In addition to its profile and level of ornamentation, color can be used to further highlight the wall.

From a design perspective, a more ornate and elaborate cornice is best suited for rooms with high ceilings. In rooms with lower ceilings, a simple profile and narrower dimension are more effective.

Wall cornice

A cove molding that is installed on walls everywhere except at openings or at corners of ceilings or floors falls into the category of wall coverings. Since they are directly attached to walls, wall coverings are generally more aesthetic than functional.

An exception to this is the chair rails and partially the wainscoting, which protect the wall from damages. Chair rails were traditionally used to prevent damages to walls caused by chairs and other types of furniture.

Paneling is a form of wall covering that is typically decorative and detailed, installed underneath chair rails. It helps to break up the wall and add visual interest and proportion to the lower portion of the wall.

Picture rails are another type of wall molding used to provide a horizontal edge where paintings or pictures can be hung. A similar type of molding is the wall frame, which typically consists of four molding pieces that form a square or rectangular shape. Wall frames are mostly decorative.

Common Materials for Mouldings

Molding is often classified by the material from which it is made. While wood has traditionally been used and is still one of the most commonly used trim materials, today there are many other options to choose from.

The type of trim material you use can vary depending on your budget and desired finish. For example, if you want a more natural finish or plan to stain the trim, then untreated wood is the best choice.

On the other hand, if you plan to paint the trim, then primed wood or other options that require less time and effort for installation may be a good choice. Let’s take a look at the most common types of materials used for trim and molding.

Plain Wood

If you want your moldings or trim to have the natural look of wood, then untreated wood is the best choice. It allows you to stain the trim and preserve the natural characteristics of the wood.

Raw wood moldings are available in a variety of wood species, including poplar, pine, fir, oak, and aspen. Each has its own unique appearance and can vary in terms of easy installation.

Primered Wood

Primered wood is natural wood that has already been primed, which speeds up installation as it does not require the initial step of priming the wood surface.

If you plan to paint the cladding, it is sufficient to use primed wood to make the installation more efficient and save time. Primed wood is generally made from less expensive wood, making it a less expensive option.

Wood Composite

A less expensive alternative to natural wood is wood composite. Made from wood fibers bonded with resins and finished with wax.

Wood composite cladding can be factory-primed and has a similar appearance to wood. It can be used both indoors and outdoors.

Medium-Density Fiberboard

Medium-Density Fiberboard (MDF) is commonly used for interior paneling. MDF is the most cost-effective option and can be painted to achieve the desired finish.

However, it does not perform well in humid or moist rooms and should not be used in exterior applications. It can work in consistently dry rooms but is not recommended for flooring or near windows and exterior doors due to moisture.

Polystyrene

Another affordable material that can be used for trim is polystyrene. It is made from polystyrene foam and can be painted with water-based paint. It tends to be less durable than other paneling materials.

However, there are several advantages to Styrofoam cladding. It is very lightweight and easy to cut, even with a knife, and can be attached with a rear adhesive, eliminating the need for nailing into the wall surface.

Polyurethane

If you’re looking for a more durable but affordable alternative to wood, polyurethane can be a good option. It usually comes pre-painted and ready to install.

Polyurethane can be cut and nailed to the wall surface just like wood. Overall, polyurethane feels similar to wood but is lighter, making it easier to work with.

PVC Moldings

PVC moldings are typically used for outdoor applications. It can withstand both moisture and direct sunlight, making it a good option for outdoor settings.

PVC trims can be cut almost like wood. In terms of cost, it is comparable to knot-free wood. PVC is available in a range of colors, so no painting is required. It can be used both indoors and outdoors.

Concluding Notes

Trim is characterized by both its placement and the material it is made of. Mouldings, a more elaborate type of trim, are also characterized by their unique profile and decorative level.

The selection of materials used for moldings can vary greatly, each with its own advantages and disadvantages. While wood has traditionally been the most commonly used material for trim and molding applications, there are now a number of modern materials that can also be used.

The choice of the best material for your specific project will depend on the desired appearance you want to achieve, the budget you have in mind, whether the trim will be installed indoors or outdoors on your home, and how labor-intensive you are willing to be with the installation.